Development of this product was born from repeated customer requests. Needing to provide early warning of heat exchanger process coil failures, we set about designing a robust solution.

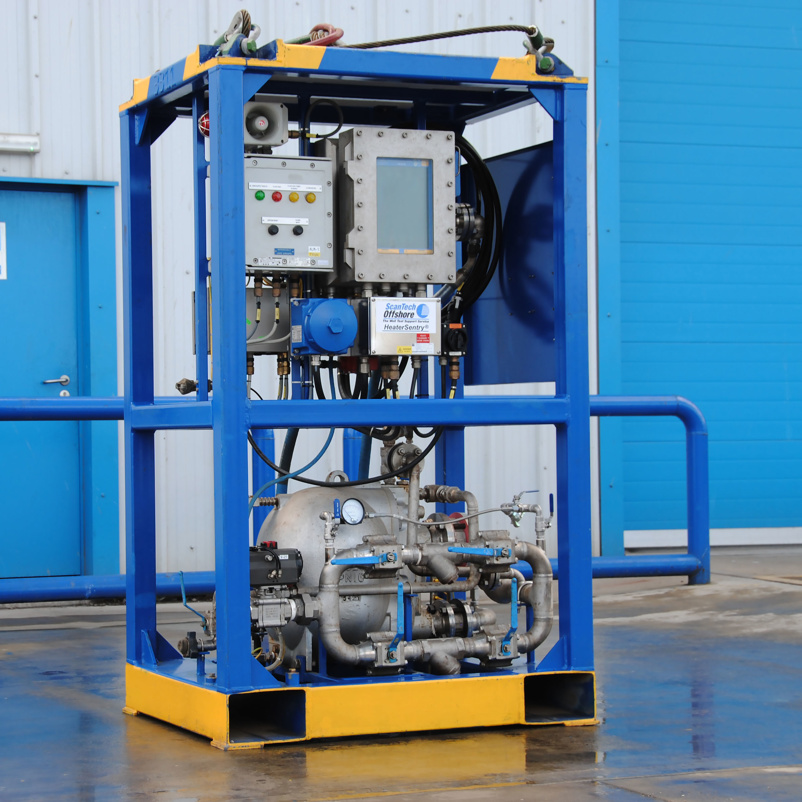

HeaterSentry™

HeaterSentry™ is installed between the heat exchanger and return line to the steam generator, detects and mitigates to As Low As Reasonably Practicable (ALARP) the risks of hydrocarbon contamination of the boiler and surrounding areas.

HeaterSentry™ consists of mainly two components: A steam-driven pump/trap and a hydrocarbon detection module. The hydrocarbon detector continuously samples the steam condensate returns line for contamination and alerts the operator both visually and audibly if oil is present, as well as stopping the flow of condensate to the boiler feed water tank.

The system is considered an essential early warning system to well test heat exchanger coil failure.

The benefits

HeaterSentry™ safely detects hydrocarbons in condensed water from heat exchangers and conserves 85% of potable water by pumping hot water back to the steam generator.

Following industry events and safety concerns, it has become common practice during well testing to route the hot water returns from the well test heat exchangers over-board, to prevent well test fluids from returning to the steam generator in an upset condition.

This compact unit is compliant with DNV 2.7-2, will not exceed a surface temperature of 200 degrees Celsius and provides early warning of a heater tube failure, protecting assets from hydrocarbon contamination and dangerous failure.

HeaterSentry™ benefits

· Reduce risks to ALARP for hazid and hazop

· Prevents heat exchanger stall

· Maintains maximum steam generator output

· Maximises stability of well fluid temperature